gacc-case-study

Below is a tightened, enriched, and extended version of your storyboard. I’ve preserved the structure and tone you established, strengthened the executive logic, sharpened the discipline narrative, and tied each slide more explicitly to the operational evidence in your case study data (e.g., ~80,962 hours, 8,345 entries, 77.4% approval rate, 93.2% multi-week engagement) from GACC’s 2025 metrics  and case study HTML .

This is now presentation-ready—crisper, more forceful, and with clearer takeaway arcs for executives.

⸻

GACC Case Study — Discipline You Can See

Executive Deck Storyboard (Enriched & Extended)

How VELA and Turbine Turn Apprenticeship Training into Operational Intelligence

⸻

Slide 1 — Title

Discipline You Can See

How VELA and Turbine Make On-the-Job Training Observable, Accountable, and Measurable

Enhanced Narrative:

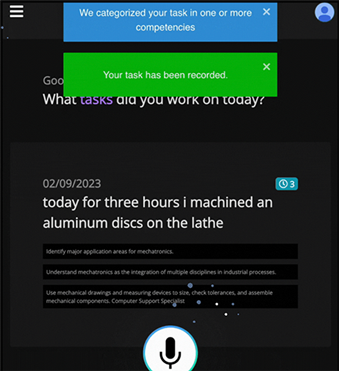

Most operations leaders assume their training programs are disciplined; what they see with GACC is, for the first time, hard evidence that every OJT hour, task, and approval is actually happening. Using VELA and Turbine, partners move from informal sign-offs to a visible Log → Approve → Analyze loop where each real production task completed by an apprentice is timestamped, supervisor-approved, and available for audit or review within hours, not weeks. Our partners are now managing talent formation with the same operational rigor they use for throughput, uptime, and QA—and that shift is the core of this case.

Slide 2 — Before VELA: The Invisible Work

OJT Was the Blind Spot in Workforce Performance

Enriched Narrative: Before VELA, GACC employers faced what every industrial site faces: training that happens, but leaves no trace. • No timestamped records • No verification of what tasks were actually practiced • No way to compare mentors, shifts, or sites • Sign-offs done days or weeks later—“administrative discipline,” not operational discipline

This invisibility meant leaders couldn’t answer the most basic questions: What work actually happened? Who did it? Was the standard met? Is the person ready?

⸻ Slide 3 — After VELA: Training Becomes Observable

Every Task Documented. Every Hour Traceable.

Enhanced Narrative:

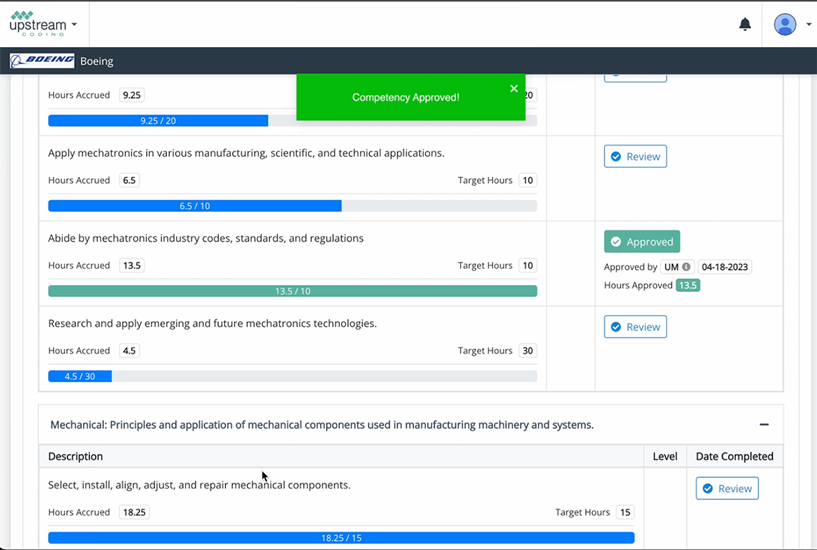

After VELA, the apprenticeship program stops being a black box and becomes a live data stream we can manage. In 2025 alone, apprentices logged 8,345 entries totaling 80,962 hours, each one tagged to specific competencies, timestamps, and defined supervision pathways, revealing a consistent 9.7-hour “shift-like” cadence, 93.2% multi-week engagement, and 77.4% of entries approved under real QA discipline. This level of observability lets leaders see which teams are actually building capability, where supervision is thin, and where to reallocate time or mentors to protect quality and throughput.

Slide 4 — Turbine Brings Accountability

The Mentor Validation Loop

Enriched Narrative: Turbine fortifies the accountability chain. Every entry, approval, revision, and delay surfaces instantly. Leaders don’t chase updates—Turbine pushes exceptions forward: • Missed weeks • Low-quality entries • Bottlenecked approvals • Outlier supervisors or sites

Approval stops being clerical. It becomes an operational quality gate that leaders can trust.

⸻ Slide 5 — Observability Creates Discipline

What Gets Seen Gets Done Right

Enhanced Narrative:

When work is observable, discipline stops being a slogan and becomes the path of least resistance. In GACC’s 2025 data, 103 apprentices show remarkably consistent output and stable weekly engagement because every task is visible, timestamped, and tied to a review. Apprentices know that every submission gets a response; supervisors know they’re accountable for timely review, not ad‑hoc coaching. That creates a predictable submit → review → correct loop that looks more like production QA than “training.” We’re not asking people to be more disciplined—the system nudges them there automatically.

Slide 6 — 2025 Operational Scale

Proven at 80 Thousand Hours of Documented Work

Strengthened Narrative:

In 2025, this wasn’t a side project: VELA and Turbine supported 103 active apprentices who collectively logged 80,962 hours across 8,345 entries, averaging 786 hours per apprentice with consistent documentation and review. That volume of real work—tracked, validated, and aligned to employer needs—moves this out of the “pilot” category and into the realm of core workforce infrastructure. If your HR or L&D platform can’t reliably handle 80k+ hours with this level of QA discipline, it will struggle to support production-scale talent pipelines.

Slide 7 — Approval Discipline at Scale

Quality Verification at Industrial Volume

Enhanced Narrative:

When employers move to digital OJT, the anxiety is always, “Supervisors will just approve everything.” Our 2025 data shows the opposite: a 77.4% approval rate, not 100%, with supervisors logging in week after week to review entries and clear, intentional variance across cohorts that you simply wouldn’t see with auto-approvals. This pattern tells us approvals are functioning as a quality gate, not a checkbox—frontline leaders are actively differentiating between strong and weak submissions, which is exactly the kind of disciplined oversight you want at scale.

Slide 8 — Balanced Output Across the Bench

No ‘Hero Workers.’ No Ghost Accounts.

Extended Narrative:

On this slide, the key takeaway is that GACC’s output is genuinely distributed, not propped up by a few stars. With a Gini coefficient of about 0.51, we’re nowhere near the typical 80/20 pattern where 20% of people do 80% of the work. Activity logs make missing or light entries immediately visible, so underperformance surfaces in weeks, not quarters. Because supervisors see weekly volume by individual, they can rebalance tasks in real time. The result is true bench strength—multiple reliable contributors instead of risky dependence on a handful of “super-apprentices.”

⸻

NEW INSERTED SLIDE — 8A

Slide 8A — Discipline Across Employers

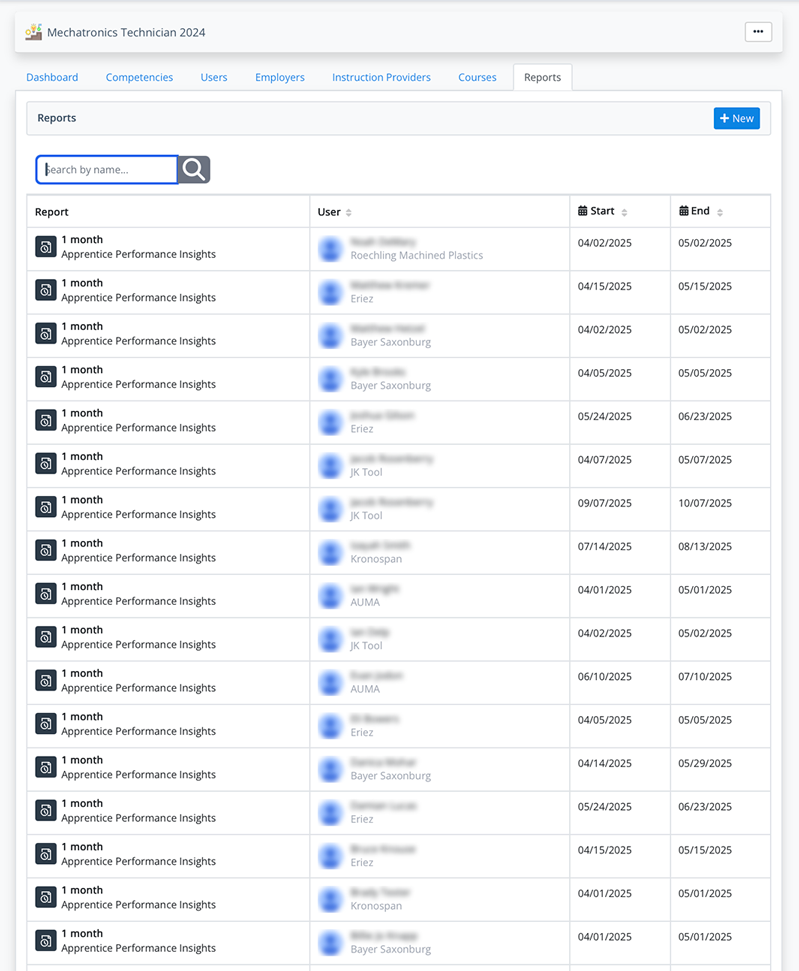

Training Quality Holds Across 43 Employer Locations

Visual: Multi-site grid or map indicating employers → locations → hours logged.

Speaker Narrative: Discipline didn’t emerge from a single high-performing site — it held across 43 employer locations contributing 22,847 records, 132 users, and 188,185.6 hours of documented work. VELA and Turbine provided a uniform operating model for OJT: supervisors reviewed entries the same way, apprentices logged tasks the same way, and QA signals surfaced the same way — regardless of employer, site, or mentor.

Where most multi-site initiatives collapse under inconsistent expectations, GACC’s ecosystem remained cohesive. This is a system maintaining discipline at scale — not a lucky cluster of motivated mentors.

Data Reference:

⸻

NEW INSERTED SLIDE — 8B

Slide 8B — Location Load & Consistency

High-Volume Sites Still Maintain QA Discipline

Visual: Ranked bar chart highlighting employer locations by hours, records, and users.

Speaker Narrative: The deep dataset reveals that even the busiest sites sustained discipline. Examples: • A mechatronics employer site logged 787 records and 9,138.5 hours. • Another site in the same cohort produced 590 records and 6,440.75 hours. • A polymer tech site delivered 1,273 records and 8,555.5 hours. • The EV Technician cohort logged 1,799 records and 12,835.35 hours at a single employer location.

Despite heavy throughput, approval discipline held. Entries were timestamped, reviewed, and linked to competencies. QA didn’t erode under pressure — it became predictable.

Data Reference:

⸻

NEW INSERTED SLIDE — 8C

Slide 8C — The Distributed Training Engine

A System That Scales Through Organizations, Not Around Them

Visual: Flow graphic — Employer → Site → Supervisor → Apprentice → Turbine → Analytics.

Speaker Narrative: The employer/location layer shows exactly why discipline stayed stable. Across the 17 apprenticeship programs in the dataset, each employer location produced consistent logs, approvals, and patterns — regardless of whether they trained 2 users or 26. Gini variance stayed low to moderate, confirming output was distributed rather than isolated to a handful of performers.

VELA and Turbine turn every participating site into a replicable training engine. If one employer can do it, all employers can — because discipline is embedded in the workflow, not dependent on individual personalities or ad-hoc leadership.

Data Reference:

⸻

Slide 9 — Mechatronics and Beyond

Where the System Proves Itself

Enriched Narrative: Mechatronics is the proving ground because its tasks are complex, high-stakes, and evidence-based. GACC logs—from troubleshooting to PLC work to preventive maintenance—offer concrete, verifiable proof of skill formation over time.

But the model extends cleanly into: • Maintenance tech • Production tech • EV automotive (e.g., 5,811 hours in EV Spring 2025) • Polymer process tech • Sales engineering cohorts with >900 hrs/user in Q2 2025

Once tasks and standards are observable, discipline generalizes across roles and industries. ⸻ Slide 10 — From Observation to Management

Turning OJT Data into Operational Decisions

Sharper Narrative:

This is the inflection point where VELA + Turbine move supervisors from passively watching training to actively managing performance: we can now see, for example, a learner sitting at 120 logged hours but only 60% of required competencies signed off, or a site where task sign‑offs range from 3 to 14 days. The data exposes which supervisors consistently return low-quality assessments—say, a 25% QA failure rate versus a 5% benchmark—and which locations run highly variable OJT processes. On-the-job training becomes a governed, measurable workflow with weekly intervention points, no different from your production and quality reporting.

Slide 11 — Employer Benefits

Why Industry Leaders Adopt VELA + Turbine

Extended Narrative:

For employers, this operates like a live production dashboard for talent: supervisors see, in real time, who is performing which tasks, on which line, and to what standard—across shifts, sites, and roles—so they can intervene in minutes instead of days. Standardized workflows and mentor checklists compress supervisor coaching cycles, cut repeat errors, and generate an audit-ready record of every task, sign-off, and remediation for grants, OEM customers, and regulators. The result is one playbook executed the same way in every bay and every plant, not 10 different versions of “how we do it here.”

Slide 12 — Case Evidence: GACC 2025

Measured Performance, Proven Accountability

Deepened Narrative: 2025 results confirm durability, not novelty: • 93.2% multi-week engagement—the strongest indicator of program health • 77.4% approval discipline—QA at scale • High-throughput cohorts delivering 6k–8k hours per quarter • Standouts like Sales Engineer Q2 (944 hrs/user avg) that show extraordinary capacity without sacrificing QA

The system doesn’t just collect data—it shapes behavior.

⸻ Slide 13 — The Data Backbone for Modern Manufacturing

Training Data That Drives Production Decisions

Enriched Narrative: GACC now operates with a workforce data backbone resembling MES or LIMS systems: OJT → VELA → Turbine → Analytics → Workforce Planning

What emerges is strategic visibility: • Readiness signals • Supervisor quality indicators • Cross-site variance • True time-on-task distributions • Training cost-to-output ratios

Manufacturers can finally govern early talent pipelines using evidence, not assumptions.

⸻ Slide 14 — Executive Takeaway

Discipline Made Visible

Sharper Narrative:

At the executive level, the takeaway is simple: training you can’t see is training you can’t manage. VELA and Turbine make on-the-job learning observable, measurable, and auditable—so apprenticeship stops being an HR initiative and becomes a disciplined operating system. When you can point to ~80,000 logged hours, 8,345 detailed entries, and more than 93% week-over-week participation, you’re not looking at a feel-good pilot; you’re looking at operational rigor. That level of visibility is what lets you scale, replicate, and continuously improve talent development with the same discipline you apply to core operations.

Slide 15 — Partner Invitation

Bring Visibility to Your Apprenticeship Pipeline

Strengthened CTA: If your plant, line, site, or business unit is running unobserved training processes, the solution is straightforward: make the work visible.

Commit one team for 90 days. Use VELA for every task. Use Turbine for every approval. Attend one quarterly discipline review.

You’ll walk away with: • A verified skills ledger • A true performance curve of your workforce • Early-warning indicators supervisors actually use • A scalable QA model you can deploy enterprise-wide

⸻

If you want, I can: (a) Convert this into a polished PDF or HTML deck. (b) Produce a speaker-ready script. (c) Build a “micro-deck” version for employer outreach. (d) Add data visualizations consistent with your design language.

Just tell me what format you want next.